|

|

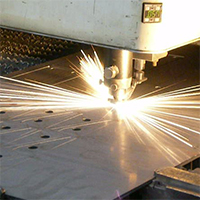

CUTTING

|

|

forming |

machining |

Welding |

|

painting |

Quality |

|

News

|

||

|

Contact |

STIMY S.A.S. is a subcontractor society, working in mechanized welding and laser cutting. Based in Loire-Atlantique (France, 44), its location is 40km south from Nantes. There is a 16 000km² indoor shed, dedicated to production. STIMY S.A.S. employs about 70 people, and the turnover is about € 10 millions.

History |

|

| 1979 | Foundation of the company. Beginning with repair of agricultural machinery. Area : 75 m², 1 person. Turnover : 100 000 Frcs |

| 1989 | Extension : 1 200m² First cutting laser bought : MAZAK 1 500 watts

25 people, turnover : 5,9 M Frcs |

| 1992 | Extension : shed and office : 2 100m² Second cutting laser bought : MAZAK 2 000 watts 35 people Turnover 13,4 M Frcs |

| 1997 | Extension : 1 000m² shed & 200m² office Acquisition of a welding robot : MRC MOTOMAN And a cutting laser : MAZAK 2 000 watts super Turbo X510 Acquisition of a STX laser : 5.10 supercharged 2 000 watts HI PRO Turnover : 27 M Frcs |

| 2001 | Investment in a computing solution (G.P.A.O.) who enable a complete following of the products. |

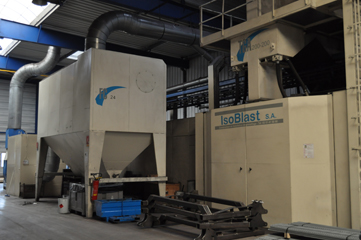

| 2002 | Laser procuction is optimized with the purchase of a production line : Construction of a 3 600m² shed to install an automated peening unit and 3 painting cabins. |

| 2006 | Extension : 800m² with 2 hanged robots HP6 X.10900 Y.1800 Z.1200 |

| 2008 | Laurence Janin and Yvan Mouillesse are nominated to the position of Directors. |

| 2009 | Certification ISO 14001 |

Go to news

Laser Cutting2 laser cutting lines MAZAK

|

|

See the video | |

|

1 laser cutting machine MAZAK

|

|

1 laser cutting machine for tubes and metal sheets : BYSTRONIC

|

| Steel cutting : Min. thickness : 1 mm Max. thickness : 20 mm |

Stainless steel cutting : Min. thickness : 0,5 mm Max. thickness : 12 mm |

Aluminium cutting : Min. thickness : 1 mm Max. thickness : 10 mm |

Tube cutting laser

1 cutting machine for tubes : MAZAK

|

|

Shearing / Punching

1 shearing guillotine AMADA GPN 840

- CN machine

- Max. capacity : 4000 mm

- Max thickness : 8 mm

|

1 punch presspoinçonneuse PULLMAX PULLMATIC 8

|

Sawing

6 ribbon saws

|

|

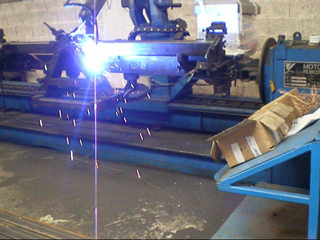

Welding

|

9 welding robots

|  |

1 welding bench

|

|

|

|

30 welding stations MIG-MAG

2 welding stations TIG

|

|

3 spotting welding stations

|

|

|

Delivery / Handling

Delivery vehicles

- 1 truck RENAULT

- 1 truck PEUGEOT Boxer

Handling material

- 1 positioner of 15 tons

- 8 positioners of 3 tons

- 17 5 tons cranes

- 15 electric hoists from 125 to 500 kg

- 6 forklifts from 1,4 to 8 tons

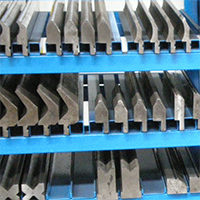

Forming

5 CN bending presses AMADA

|

|

|

1 bending press RAS GIGABEND

|

4 bending presses "à col de cygne"

|

|

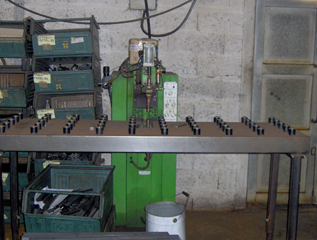

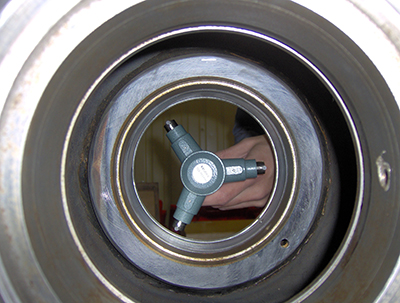

Machining

4 CN milling machines

|

|

|

3 CN towers

|

|

|

|

2 bras de taraudage

|

Painting

A painting line dedicated to iron angles

|

|

|

|

A painting line dedicated to other pieces

The handling of pieces through the shed is assured by an aerial conveyor with dual carriageways, for a length of 285 meters. |

|

|

|

|

|

|

|

|

|

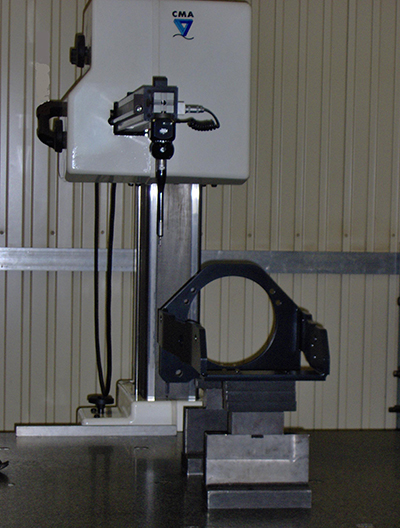

Quality1 3D machine

|

| Manual control in room and shed with various tools,(electronic height gauge, internal and external micrometers, axis, portable hardness measuring device, ...) |  |

|

1 portable measuring arm :

|

Certification 14001 |

|

News |

|

| 2013 | Laser tube 8 cutting lasers 9 welding robots |

See the video | |

|

Extension : painting shed -> 750 m² |